Succes Story

Bahlmann veal is Germany’s largest veal producer. The small town of Lindern is home to one of the most modern slaughterhouses in the country, and this is also where we find Bahlmann’s feed factory. DGS was able to make a significant contribution during the modernisation of the slaughterhouse. Together with Managing Director Dirk Vagelpohl, we look back on this project.

2023, Lindern, GermanyBeef & Veal

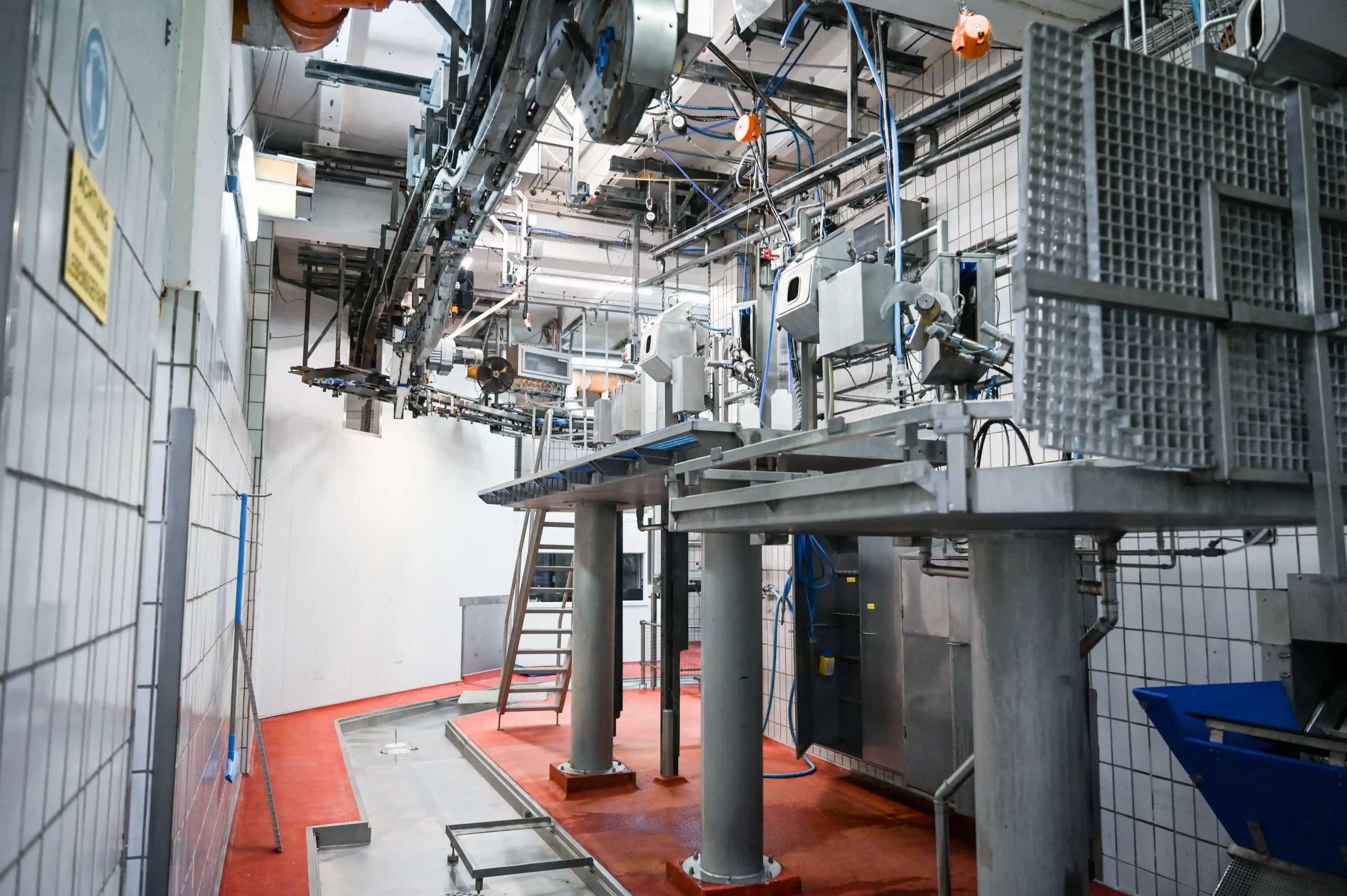

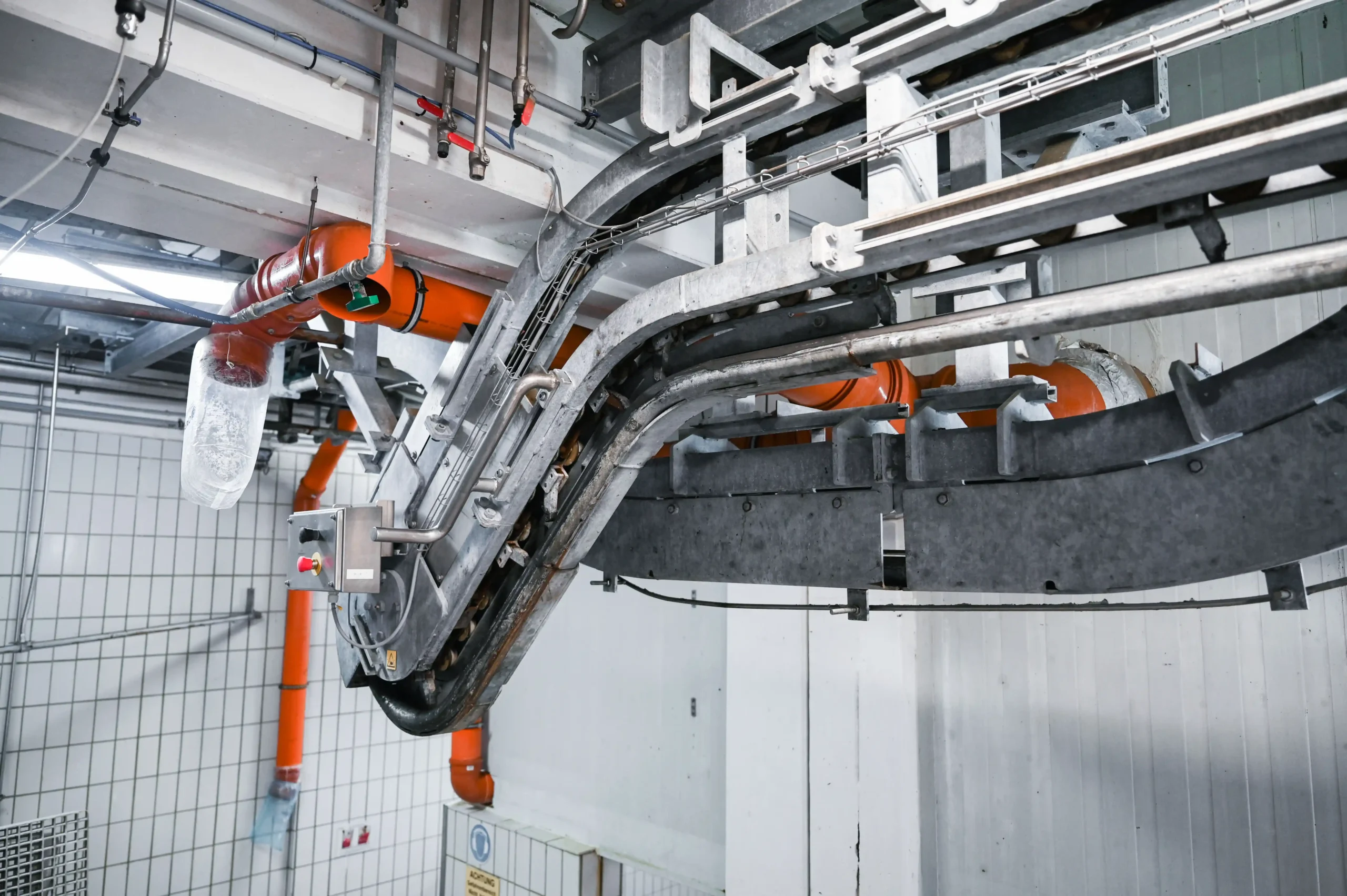

Through a befriended company and past contact, Bahlmann came into contact with DGS. To get a good impression of DGS’ previous work, a delegation from Bahlmann visited several completed projects. This impressed them so much that cooperation was established. DGS supplied several solutions for the modernisation of the slaughterhouse in Lindern. First of all, two innovative corridors with accompanying stunning cages were installed. One flotation lane with stunning cage for cattle and one for calves. Further down the slaughterhouse, DGS supplied front de-skinning platforms, a de-skinner with special skin removal, overhang systems and degreasing platforms.

Challenges

The project at Bahlmann presented the necessary challenges, Dirk Vagelpohl explains: “there was limited space and the ceiling is relatively low. Also, the work had to take place during slaughtering, which was not always easy’. Because of the low ceiling, the dehider was built several dozen centimetres into the ground. This provides a unique way of hide transport: the hides are transported under the floor after skinning. They are then picked up by an automatic crane bucket and deposited in the container. Rejected hides are filtered out here and do not enter the container.

A little further back in the slaughterhouse are the two special cattle races with stunning cages. This is a component that DGS owner Henk ter Avest is particularly proud of: “the races had a somewhat longer start-up period, but this provided industry-leading solutions”. Thanks to the special driving corridors, both cattle and calves are calmly guided to the stunning cage without distraction and stress. The stunning cages themselves are virtually silent to ensure the highest level of animal welfare. In addition, the stun cage for calves is fully customised.

Satisfied

The conversion has now been completed for some time and the slaughterhouse is running at full capacity. Bahlmann is very satisfied with the work done and the cooperation with DGS. DGS knows its business and a solution was found immediately for every problem. It was an exciting project for all of us, which also involved a few hurdles. Together, we managed to overcome these hurdles. Looking back, we chose the right partner for the modernisation of our slaughterhouse and we are sure that we will carry out further projects with DGS,’ Dirk concludes.

“Looking back, we chose the right partner to modernise our slaughterhouse”

Dirk Vagelpohl