Succescase

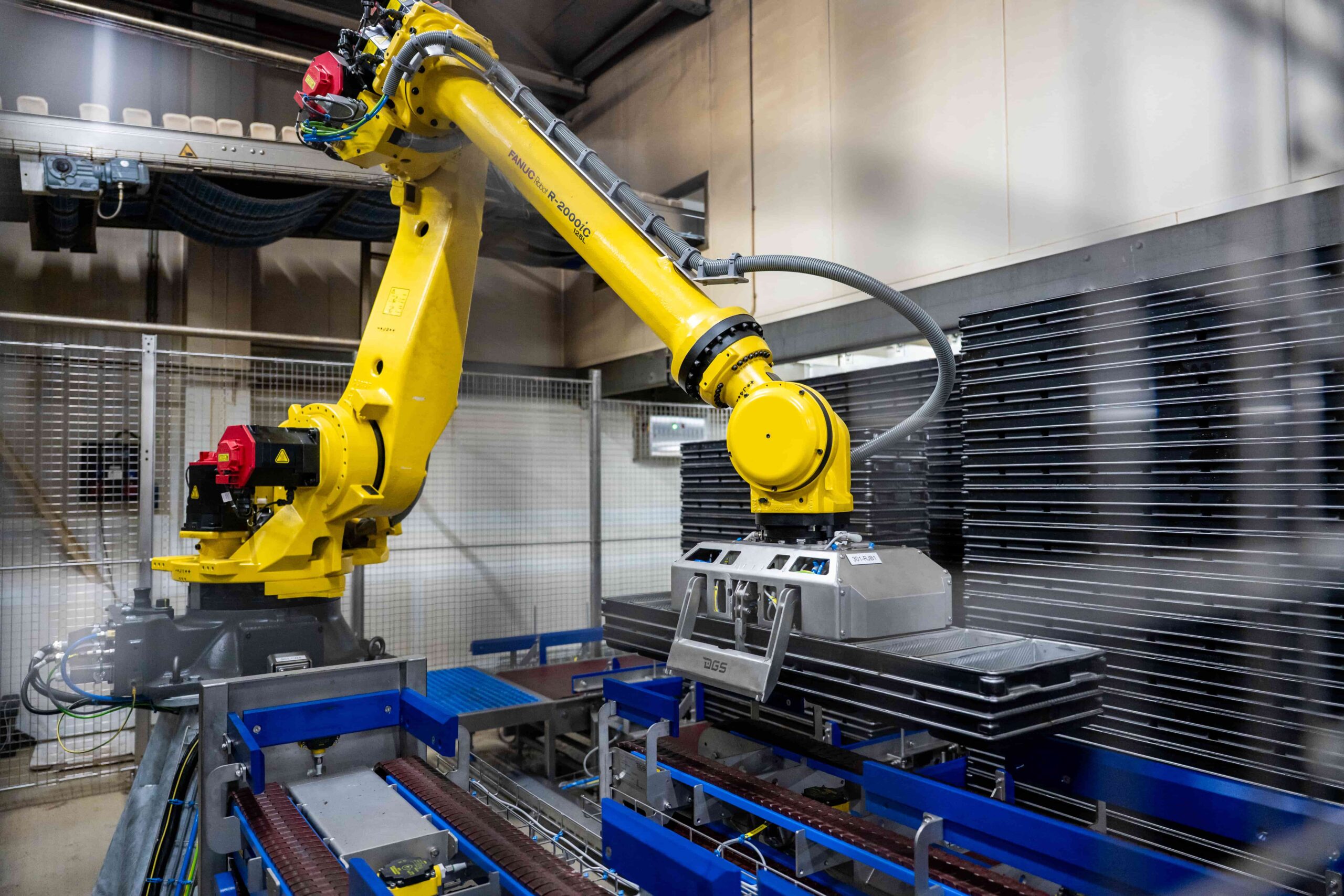

Bakery De Paauw, a modern bakery with a strong focus on automation, has once again partnered with DGS to further optimize its production process. Previously, an automated storage and buffer system was implemented, including two robots for stacking and unstacking lids on baking pans. Now, the exchange of baking pans has also been fully automated.

2025, NetherlandsTrust in collaboration

One of the major challenges in this project was the limited space. By using robotic technology, a compact and hygienic solution was created that supports a stable and continuous baking process. The fact that Bakery De Paauw once again chose to work with DGS shows the trust in this partnership and rightly so: this project was successfully completed as well.

“This project has taken our production to the next level.”

Klaas Fuite, Owner of Bakery De Paauw