Succes Story

With eight different locations in Belgium, Belgian Pork Group is a major player in both the national and international pork market. One of these locations is Locks, situated in the industrial area of Ghent, where pork is processed and frozen in various ways. To future-proof the company, a few years ago, they opted for extensive automation. DGS was brought in for three critical components: intralogistics, the plate freezing department, and a repacking line for boxes.

2025, BelgiumIncreased efficiency and productivity

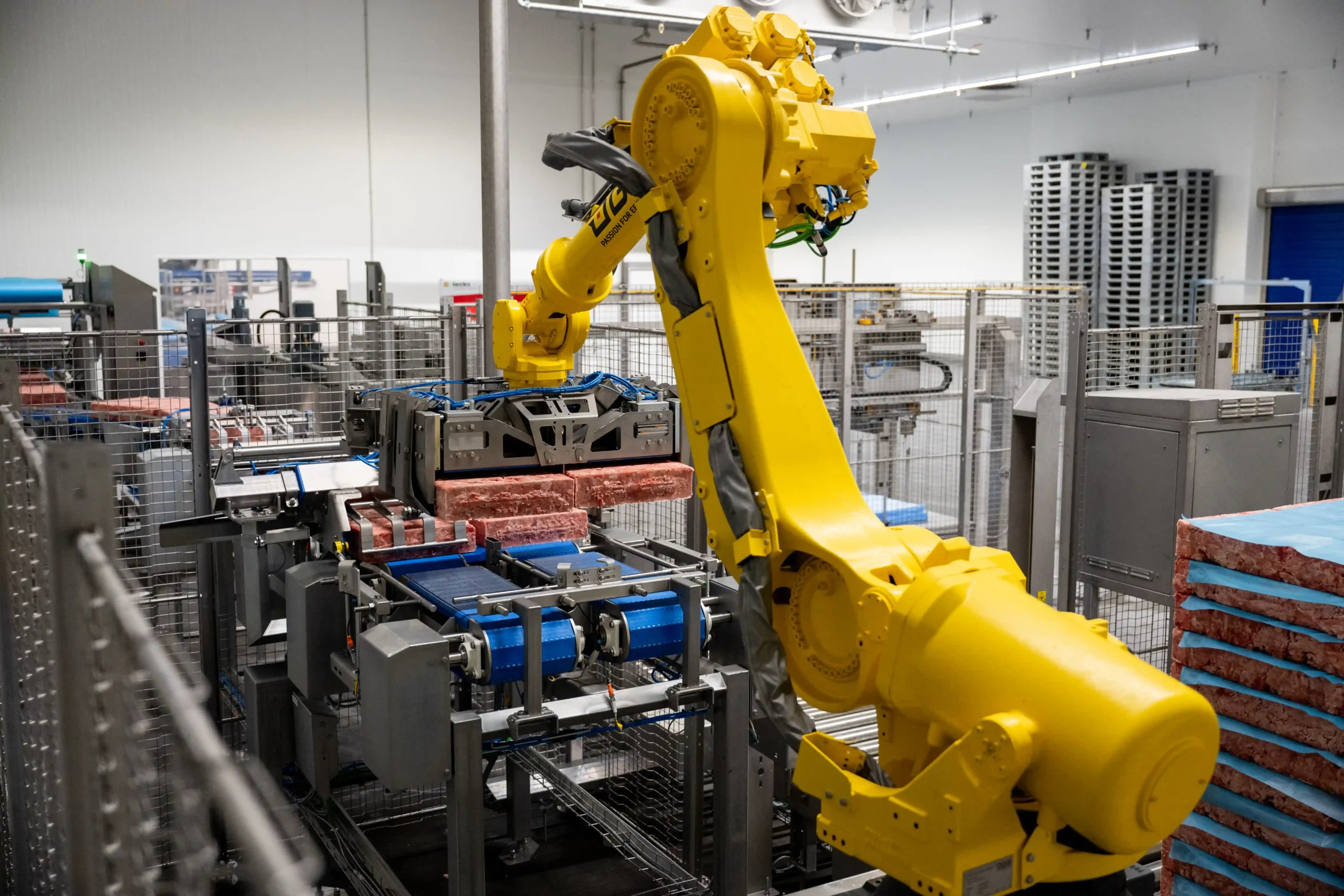

As a specialist in frozen products, Locks also invested in an innovative plate freezing line, provided by DGS. The line includes a hopper with a dolav tipper for freezer loading, frozen block transport, and block palletizing. During palletizing, pallets are automatically stacked and fitted with a base sheet, while robots add foil between layers.

Thanks to this extensive automation, the entire line is operated by a limited number of operators per shift. With an impressive output of 100 to 120 tons per week, efficiency has significantly increased. Moreover, product quality is excellent, according to Glenn: “Plate frozen products are rare in Belgium, and our customers are incredibly satisfied with our pallets. We’ve proven that we can set a new industry standard.”

Surprisingly Smooth Collaboration

Initially, the transition to automation was a daunting step for Locks. The big question was whether the changeover would go smoothly. However, now that all systems are running, all doubts have been dispelled. “Honestly, the collaboration with DGS exceeded expectations. We received great support, thorough training, and DGS made it clear from the start that we were not just a number, but a valued client they were willing to invest in. From day one until now, I can’t find anything to criticize about the partnership,” concludes Glenn.