Succes Story

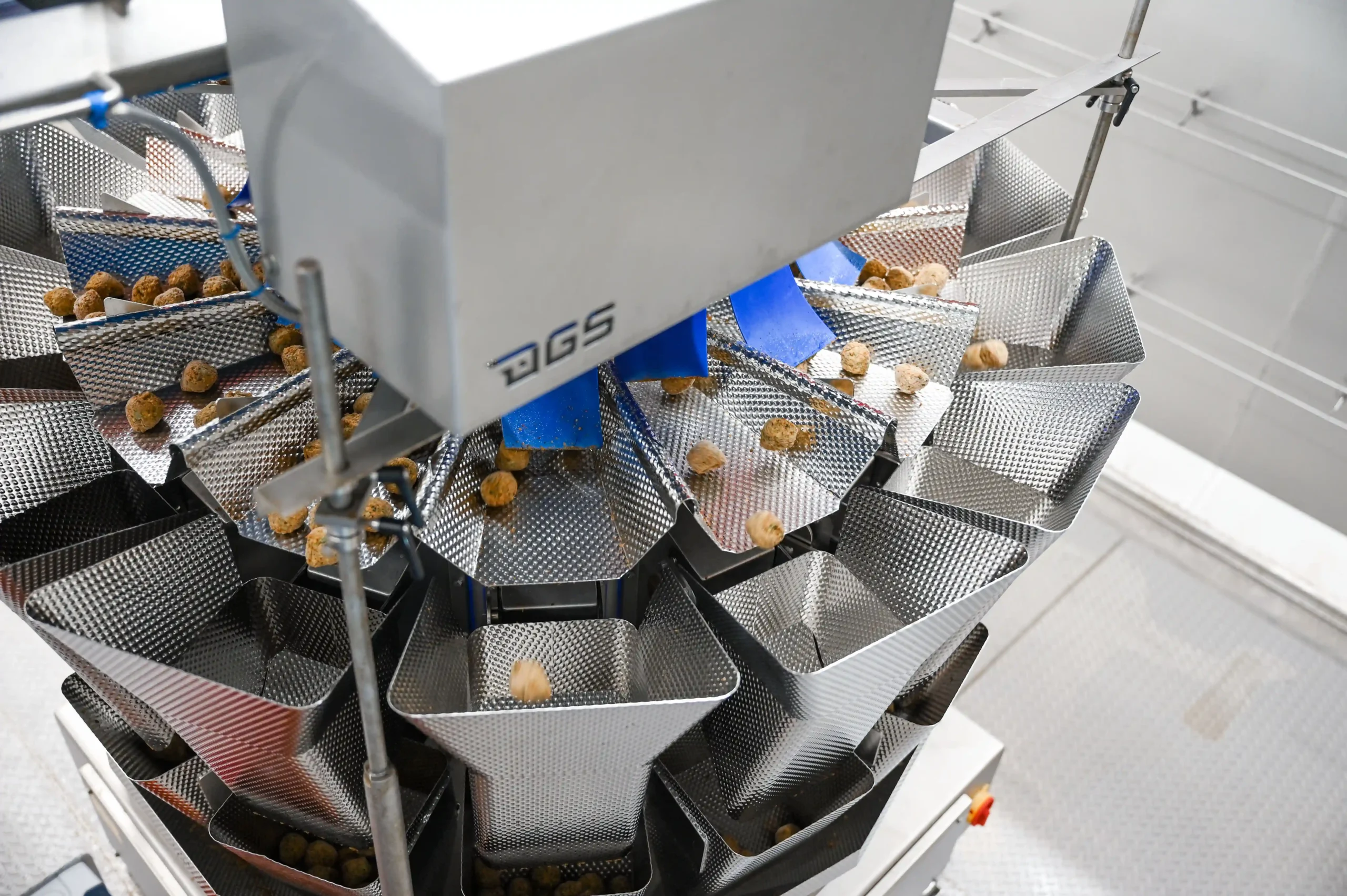

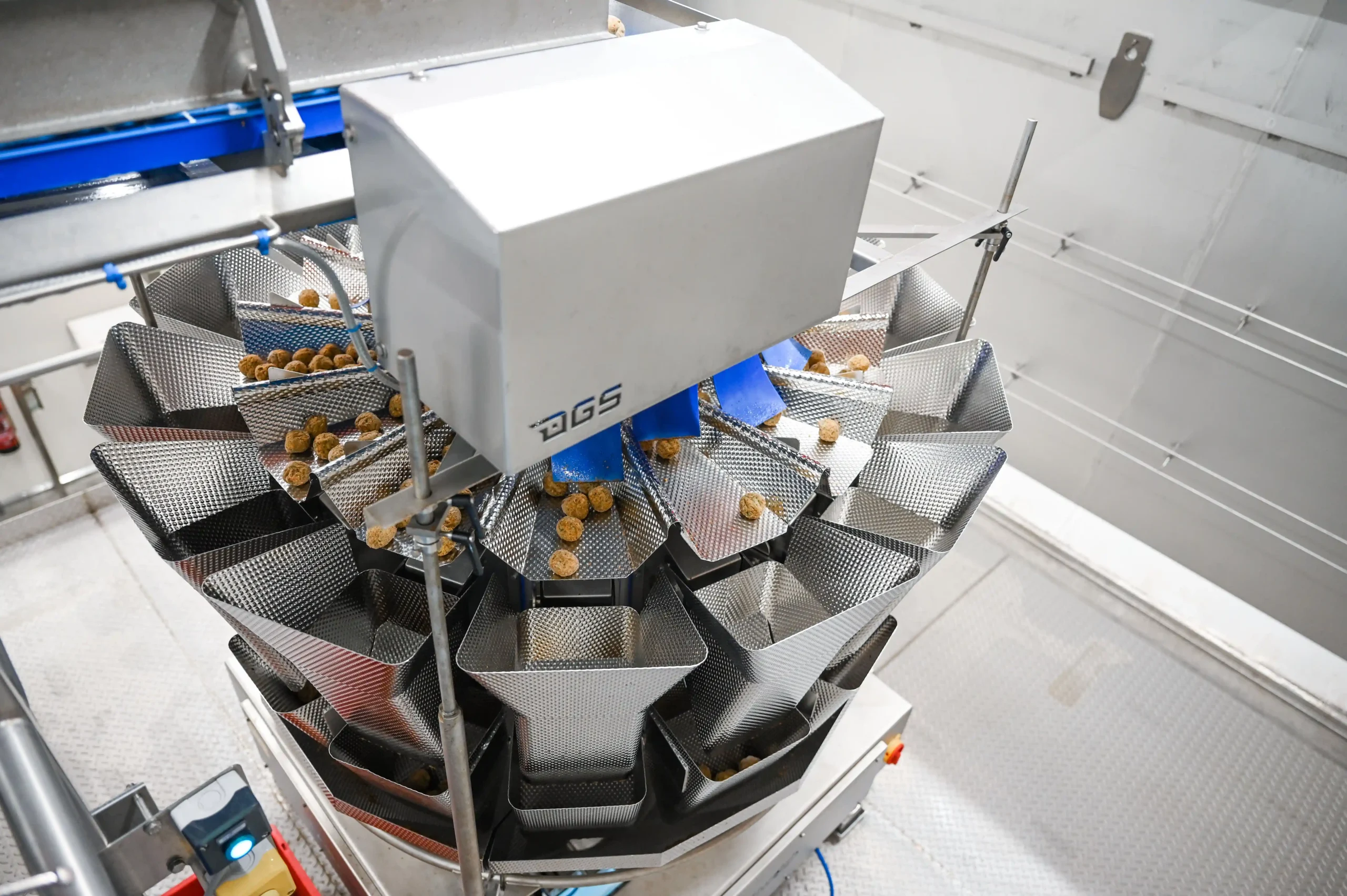

DGS has recently completed a project for the high-care department of vegetarian foodproducer Schouten Twente. The project focused on hygiene and optimisation, with the main challenge being the limited space. The result? A custom-made platform that not only meets strict hygiene standards, but also delivers remarkable efficiency.

2023, NetherlandsReduced FTEs and Increased Output

The platform at Schouten is far from standard. This is primarily due to the limited space within the high-care area, as Arno also points out: ‘The challenge is that we first need to go up with the platform and then work our way back down. During this process, the upper part is completely wet cleaned while there’s a machine underneath that needs to stay dry. That’s why the upper section of the platform is fully enclosed and equipped with a drainage system to prevent water from dripping down.’ Furthermore, the new high-care facility is much more efficient than the old one. Staffing has been reduced from eight to two employees, while the output is higher than before.

Short Communication Lines

Both the collaboration with DGS and the new platform have been very well-received at Schouten. According to Arno, this is primarily due to the short communication lines that DGS employs. “Recently, a DGS technician was here. We encountered some issues with a specific product, so I asked him if he could reprogram the machine differently. This was not a problem, and he promptly took care of it. I greatly appreciate these kinds of things: not making them bigger than they are and avoiding bureaucratic fuss.”