Succes Story

T. Boer & zn has been a valued customer of DGS since its inception, playing an essential role in the company. A few years ago, T. Boer & zn faced a new challenge: optimizing the valorization of by-products to enhance both shelf life and quality. DGS responded by developing various tailored solutions, resulting in a complete modernization of the slaughterhouse.

2023, NetherlandsInnovative By-Product Separation Method

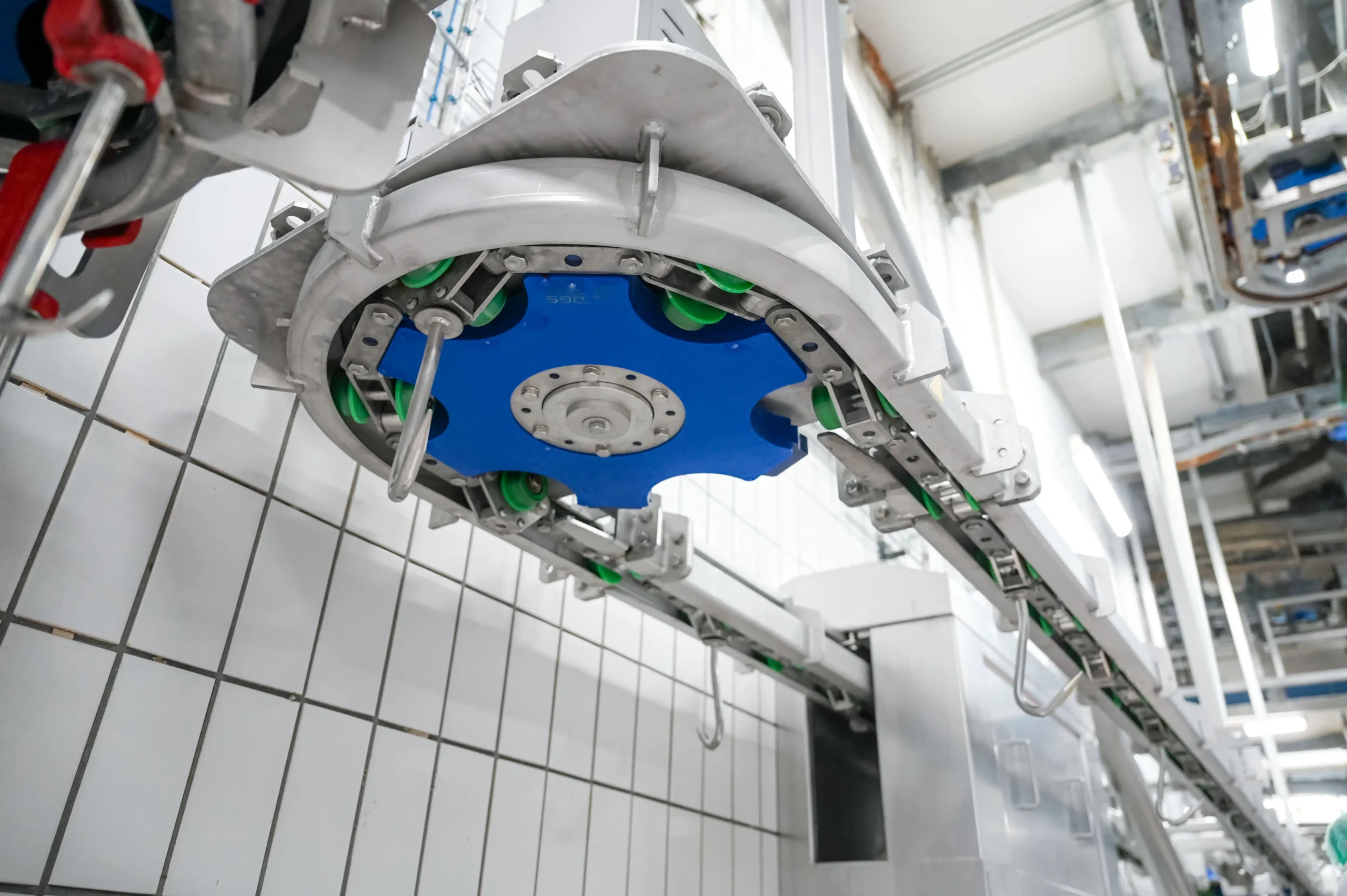

During the slaughterhouse modernization, a new organ conveyor was installed, separating the red and white organs of the carcass. However, all organs passed simultaneously in front of the inspector. By hanging the head, red organs, and liver in the correct order, they were automatically sorted at the so-called ‘Theo junction,’ named after co-creator Theo Legters. The head and red organs go one way and are cooled hanging with cold air, while the liver is cooled with water and air in a separate cell.

After carcass approval, it passes through the Smart Stim, where excess energy is removed to enhance meat quality.

Improved Hygiene and Meat Quality

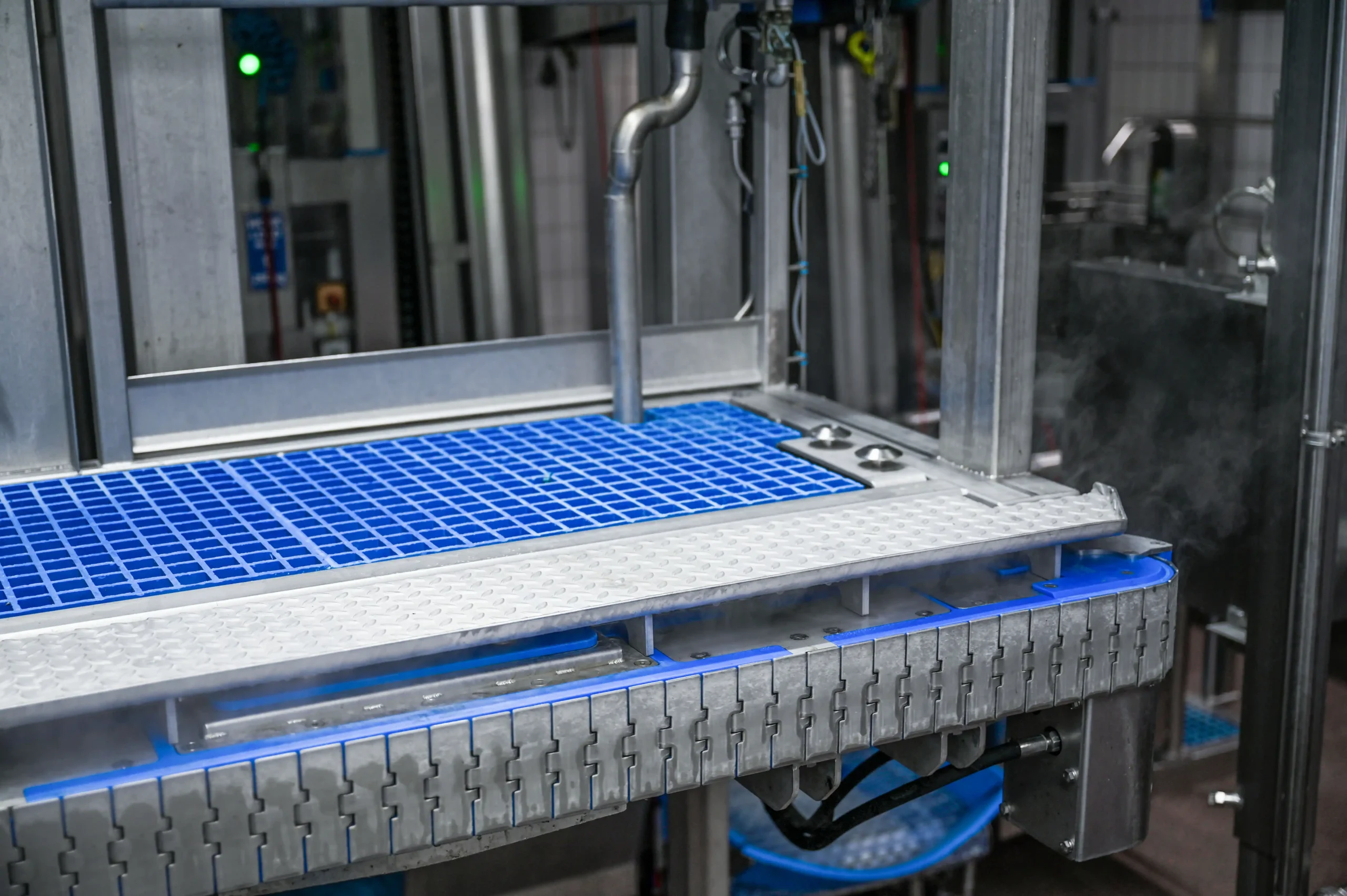

Hygiene is crucial for meat quality. To ensure the highest level of hygiene, DGS delivered custom washing and sterilization tables, fully tailored to the specific requirements of T. Boer & Zn. Additionally, installed anti-contamination belts contribute to enhanced hygiene. Another contribution is the unique method of separating the rumen and its contents, where the rumen is supported to prevent a significant fall, keeping everything intact. This prevents stomach content from reaching the meat, minimizing contamination. Finally, DGS developed and installed various innovative compressed air conveyor.

Further Developments

Work continues, with the upcoming installation of a waste disposal system from HYTT, a recent addition to the DGS group. This closed suction system ensures a highly hygienic transport of slaughter waste. Furthermore, DGS implemented a refurbishment line for updating rejected carcasses, reducing the number of discarded carcasses and minimizing waste.

“DGS doesn't follow industry standards; they set them. Working with them has not only optimized our processes but has been a journey into the future of meat processing.”

Ronald Jansen