Hygienic Transport of Slaughter Waste

Hygienically transporting food is a crucial yet challenging aspect of food safety. Unfortunately, this process often receives insufficient attention despite the significant benefits it can offer. DGS, together with its sister company HYTT, provides an innovative solution based on vacuum technology and closed pipeline systems. These systems ensure not only efficient and hygienic transport of waste but also offer advantages in space saving, waste upgrading, and cost reduction.

Our vacuum systems suction product streams, waste, and animal by-products from the production area to a central location elsewhere in the factory. By using a closed system, the production area remains cleaner and safer, with significantly less risk of cross-contamination. This solution is suitable for a wide range of slaughter waste, including intestinal contents, hide pieces, floor waste, pig hair, organ waste, and more.

- Upgrading waste and by-products

- Reduced manual labor

- Improved hygiene in production areas

- Easily expandable number of suction points

Personal advice

We are happy to discuss the possibilities with you

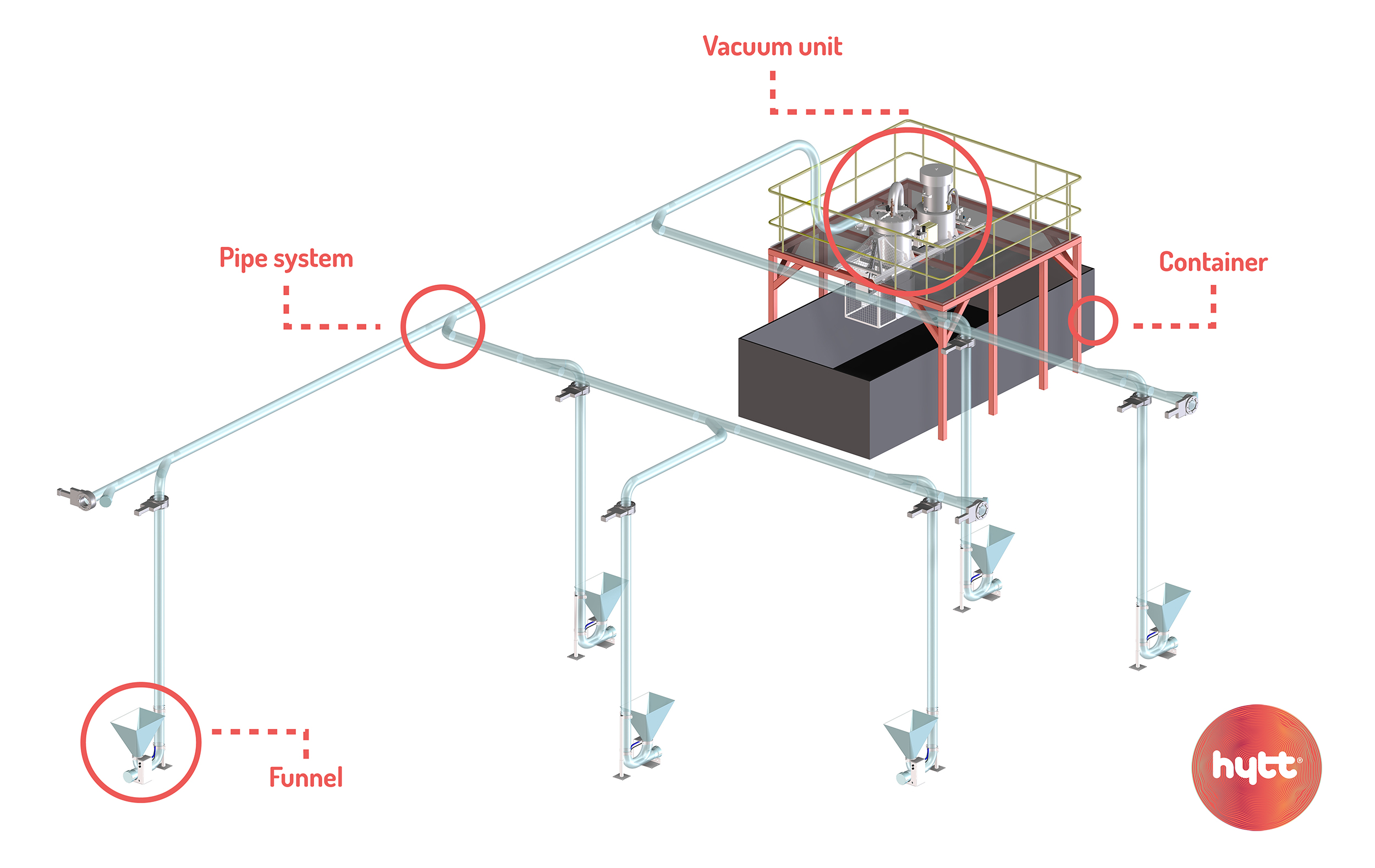

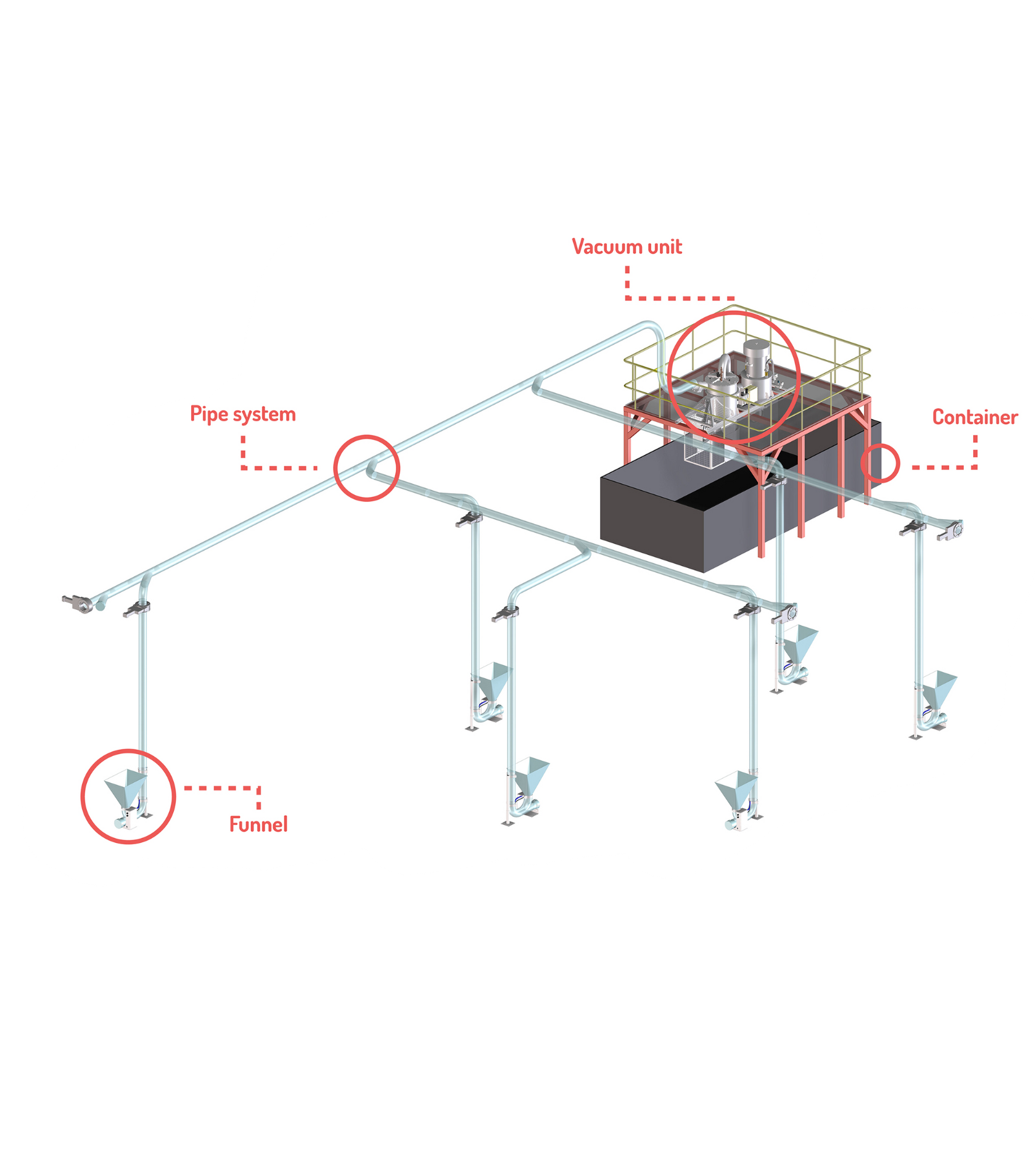

Operation of the conveyor system

Our innovative closed conveyor system uses vacuum technology and closed pipe systems, ensuring efficient and safe waste disposal. This solution offers numerous advantages and works as follows:

1. Central Vacuum Generator: The core of the system is a powerful central vacuum generator. This provides the necessary suction to transport waste and by-products to a central container quickly and efficiently.

2. Multiple Funnels: Multiple funnels are installed scattered throughout the production area. These points are installed directly at the areas where waste is generated, such as at cutting tables, processing lines and other critical points.

3. Closed Pipe System: Waste is disposed of through a closed pipe system. This system prevents waste from coming into contact with the environment, drastically reducing the risk of contamination and spread of bacteria.

4. Central Container: All disposed waste is collected in a container located at a central location in the plant. This container can be easily emptied and cleaned.

Benefits of efficient waste management

The closed vacuum transport system offers slaughterhouses numerous advantages for efficient and hygienic waste management. This innovative system removes waste and by-products immediately from the processing area, resulting in a hygienic working environment and preventing cross-contamination. Its durable and modular design makes integration into both existing and new processes easy.

By minimising manual labour, the system reduces labour costs and improves ergonomics for employees. In addition, it lowers internal transport costs and reduces water consumption. The upgrading of waste and by-products contributes to additional sustainability and reduces waste. With our waste transport system, slaughterhouses can benefit from a cleaner, safer and more cost-efficient working environment.

- Direct removal of waste from the production area

- Reduction of labour costs

- Reduced internal transport costs