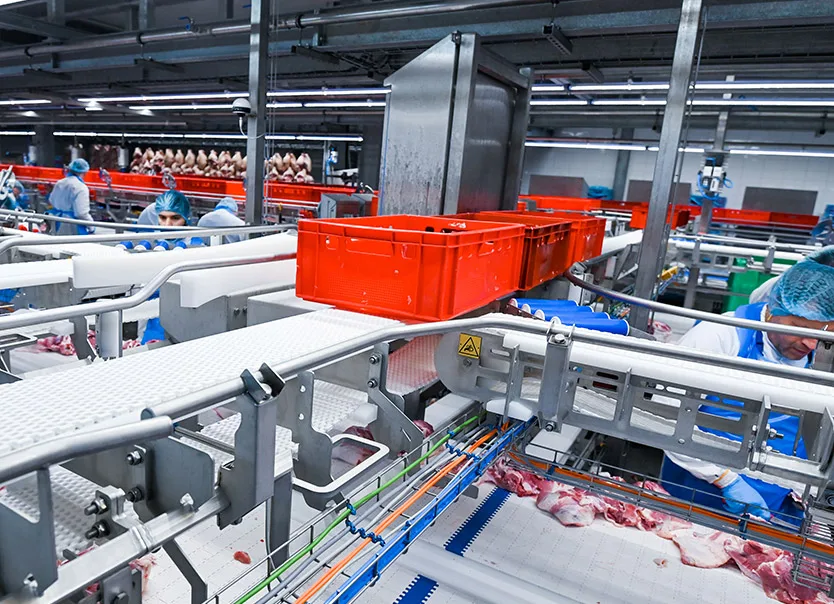

Logistic solutions in the deboning room

Full destination control of internal crates is crucial in any meat logistics system. That is why DGS offers customer-specific solutions. The installations consist of modular conveyors for horizontal transport of crates and lifts for vertical transport. Identification of each crate and its contents is very important. Therefore, the logistics system can use RFID (Radio Frequency Identification) or barcodes as identification on each crate to ensure full control over the production line.

- Automation for both crates and (meat) products

- Identification via RFID chips and barcodes for full control

- Customer-specific solutions

Besides conveyor systems for crates, we also offer solutions for product logistics. For example, we use various conveyor belts to further transport the split carcasses to workstations for further processing or transport. Usually, technical parts are further processed ‘in line’, but it is also possible, for example, to sort out hams for subsequent hanging in the cold store.

Personal advice

We are happy to discuss the opportunities with you.