Successful Collaboration within DGS Group

In 2019, HYTT delivered a solution for Peoria Packing’s slaughterhouse. Due to satisfaction on both sides, a collaboration quickly followed for Peoria Packing’s new production facility. Alongside HYTT’s vacuum system, DGS was asked to handle the logistics. This project is an excellent example of collaboration within the DGS Group in the United States!

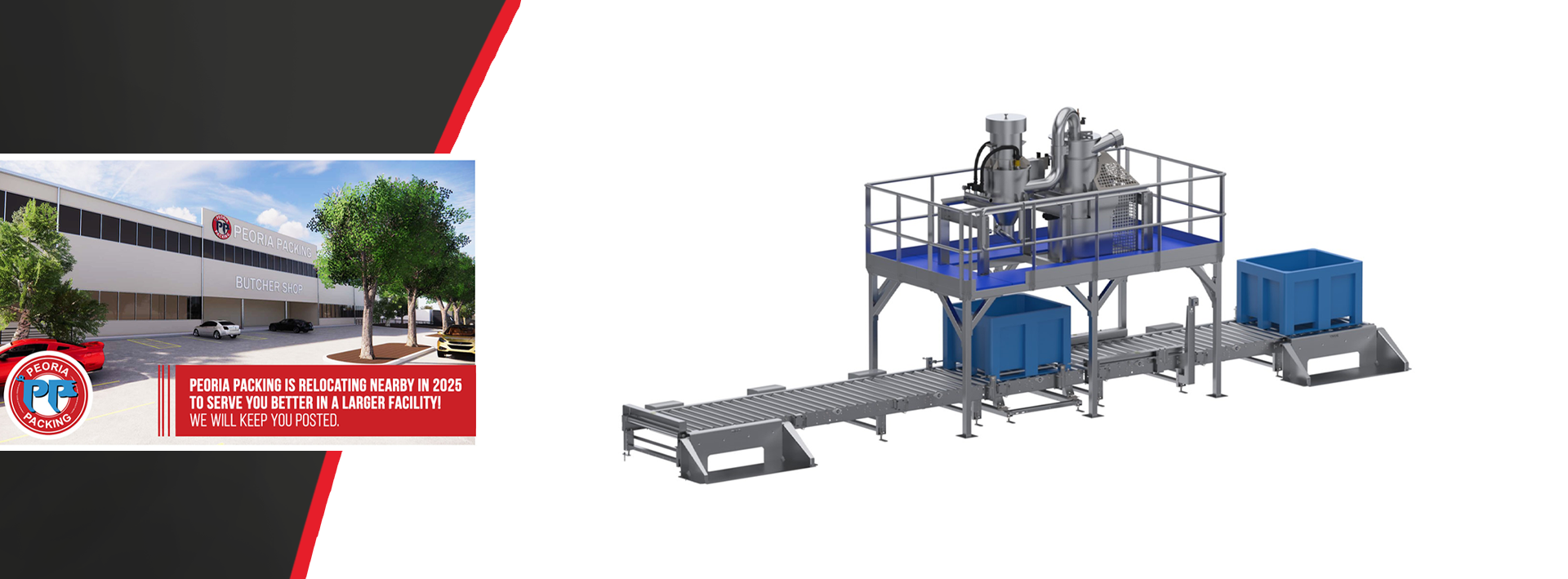

Automated Logistics Solution

Peoria Packing sought an automated solution for internal logistics for their new factory. This led them to DGS and HYTT. DGS supplied roller conveyors for Dolav bins and a Dolav scale for weight control. HYTT installed a vacuum blow system with five suction points for hygienic transport of crushed bones. These systems achieve a capacity of four Dolavs per hour.

Seamless Collaboration

The collaboration between DGS and HYTT was very positive. The solutions seamlessly complemented each other, resulting in efficient and effective process automation. Thijs Waanders, Sales Manager at DGS, commented: “I am very pleased with the collaboration with HYTT on this project. By combining our strengths, we were able to provide Peoria Packing with a complete and reliable solution. This project demonstrates the power of collaboration and innovation within the DGS Group.”

The partnership within the DGS Group proved invaluable for this project. It shows how different companies within the group can strengthen each other and jointly develop innovative solutions. The success of this project highlights the potential and synergy within the DGS Group, contributing to the further growth and development of our joint customers.