The most innovative production technology

Meat products, such as chicken breast, ham, cooked sausage and liver products, are usually finished or “cooked off” after production to ensure food safety. This finishing, especially with indirect heating (steaming, boiling or grilling), is an energy- and time-consuming step in the production process. This is why RF Food Systems, a sister company of DGS, has developed a new radio frequency (RF) cooking technology. This system offers a sustainable and cost-efficient alternative that delivers at least equal, but possibly even better product quality.

RF technology is an efficient, continuous heating method that cooks products faster and more evenly than conventional batch steam treatments, while maintaining or even improving texture, colour and flavour. Suitable for cooking any type of meat at temperatures between 50 and 98 degrees Celsius, this technology’s high output and cost savings make it an ideal solution for manufacturers with large production volumes.

- Significantly reduced production time: higher output, more flexible and quicker response to market demand

- Better process control and inline, continuous system

- Even and fast heating from the inside

How does it work?

Radio Frequency waves are waves with a frequency between 3 and 50 Mhz. These waves tilt, oscillating molecules in a product creating heat. RF waves are homogeneous waves that heat the product from the inside. The penetration depth of the waves into a product is about 5 to 7 cm. RF waves enable a heating rate of 5-10 degrees per second. This is very fast compared to other heating techniques.

Benefits of RF

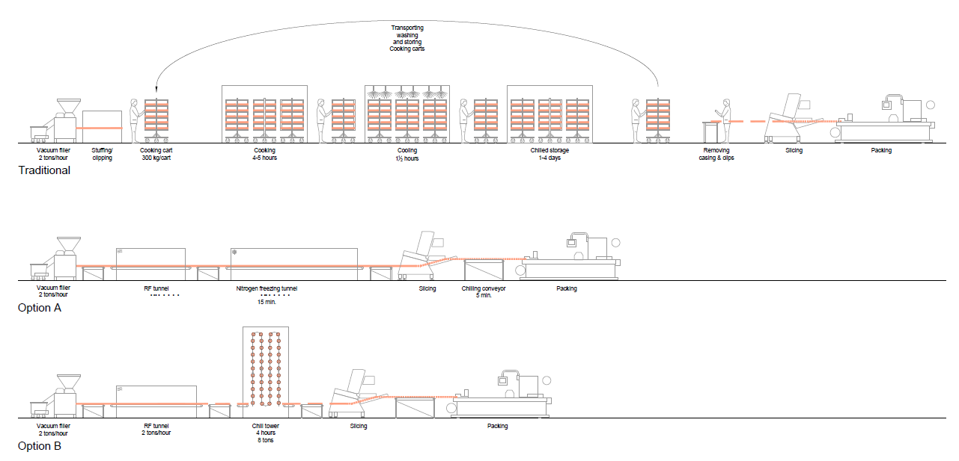

RF technology offers the possibility of moving from a batch process to a continuous process, which means a reduction in lead time. Depending on the application of RF technology, this can bring cost benefits in terms of energy, labour and material consumption.

Some of these benefits include:

- Uniform and immediate temperature rise in the product, speeding up the production process

- Improved product quality & less labour intensive

- Better process control

- Environmentally, there are also benefits. RF technology does not use fossil energy but only electric

- Stand alone set-up because no boiler house is needed. This can mean lower investment costs