Horizontal freezing for consistency

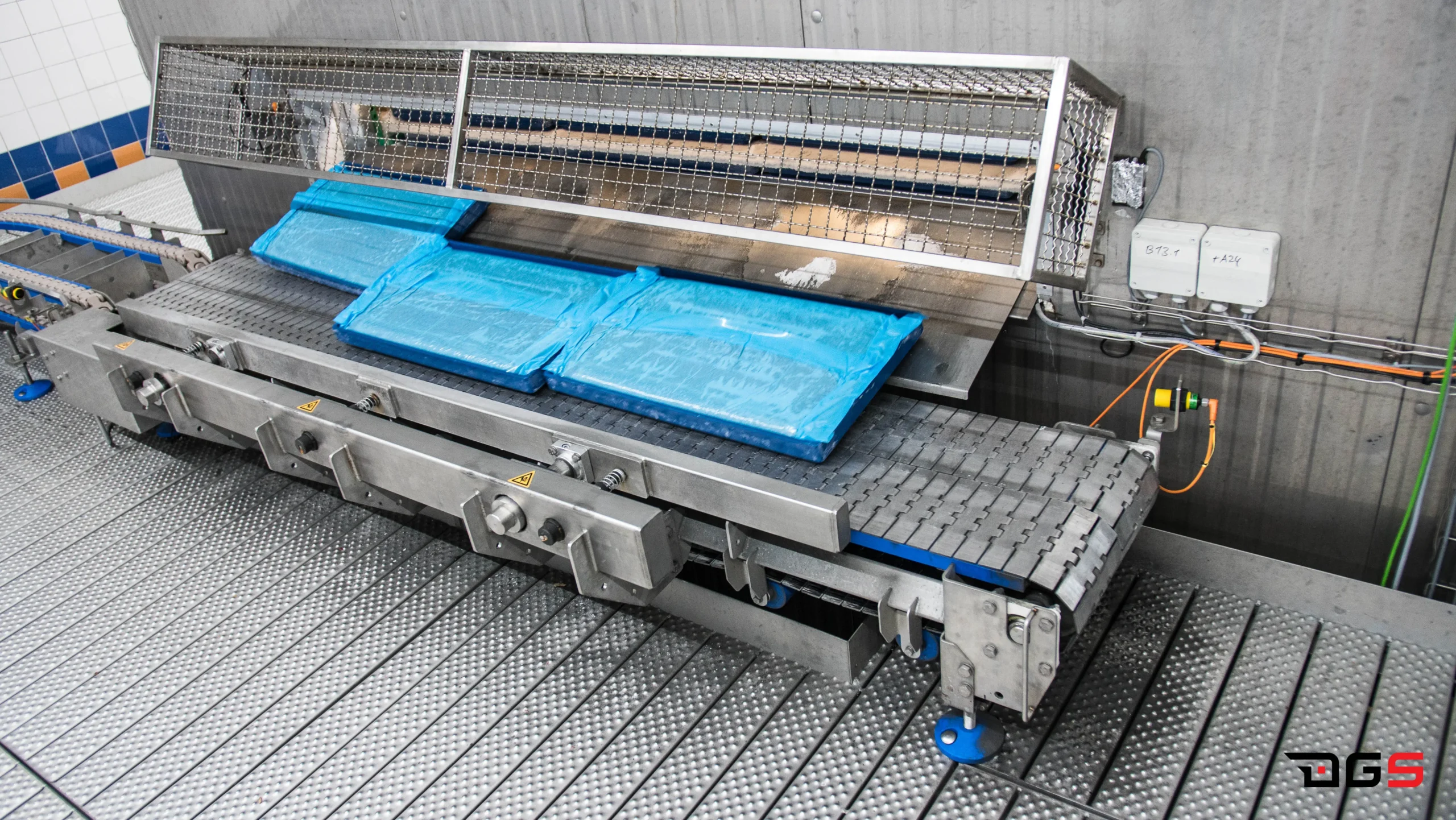

After the meat is pumped into a tray, it passes through a horizontal freezer. Various options can be added to the line from filling to entering the horizontal freezer, depending on customer preferences. After filling the tray, it can be weighed for consistent production. Fresh meat can also be filled into bags, ready for freezing.

Horizontal freezing ensures precise filling of the tray, resulting in a consistent end product in shape and weight. This makes the end products easy to process in subsequent steps such as packaging or palletizing. The system is modular and can be expanded with various options, such as naked freezing, packaging in foil, and weighing.

- Consistent end product

- Modular system construction

- Naked freezing or packaged in foil possible

Personal advice

We are happy to discuss the possibilities with you.

Automatic Unloading and Palletizing

While manual unloading of frozen blocks is possible, we also offer automatic systems for increased efficiency. After the freezing process, the blocks are automatically conveyed from the horizontal freezer to the metal detection via conveyor belts. Then, they are formed and stacked on the pallet via the robot palletizer. Depending on the speed, the robot can palletize both per block and entire layers. At DGS, we provide various solutions, from filling to palletizing, to ensure an efficient and hygienic process.

More information