Improved meat quality: Sanitary solutions for slaughterhouses

A hygienic slaughter process contributes to meat quality. Therefore, DGS offers various sanitary solutions to not only ensure but also improve hygiene in slaughterhouses.

Our sanitary systems are designed to prevent cross-contamination during the slaughter process and can be integrated throughout. We provide sterilizers for cleaning knives post-slaughter and closed transport systems automatically removing waste to containers.

Additionally, we deliver cleaning systems for conveyors, disinfection of organ hooks, and stainless-steel chains to prevent oil leakage. Our platforms feature apron showers, tool sterilizers, and optional anti-contamination belts.

With DGS solutions, we assist abattoirs in maintaining hygiene standards and improving meat quality.

- Enhanced meat quality

- Cross-contamination prevention

Personal advice

We are happy to discuss the possibilities with you

Sanitary Solutions for Platforms

For platforms, we offer various sanitary solutions. In addition to apron showers, sterilization units for knives and other tools can be installed.

To ensure that the platforms themselves remain clean, they can be equipped with anti-contamination belts. These stainless-steel conveyor belts act as a protective buffer between the carcass and the platform, avoiding direct contact. Thus, the belts prevent rejected and potentially contaminated carcasses from touching the platform. With an automated cleaning process, they ensure maximum hygiene and minimize the risk of bacterial spread.

DGS’s anti-contamination belts are versatile, user-friendly, and require minimal maintenance, providing a cost-effective and sustainable solution for abattoirs.

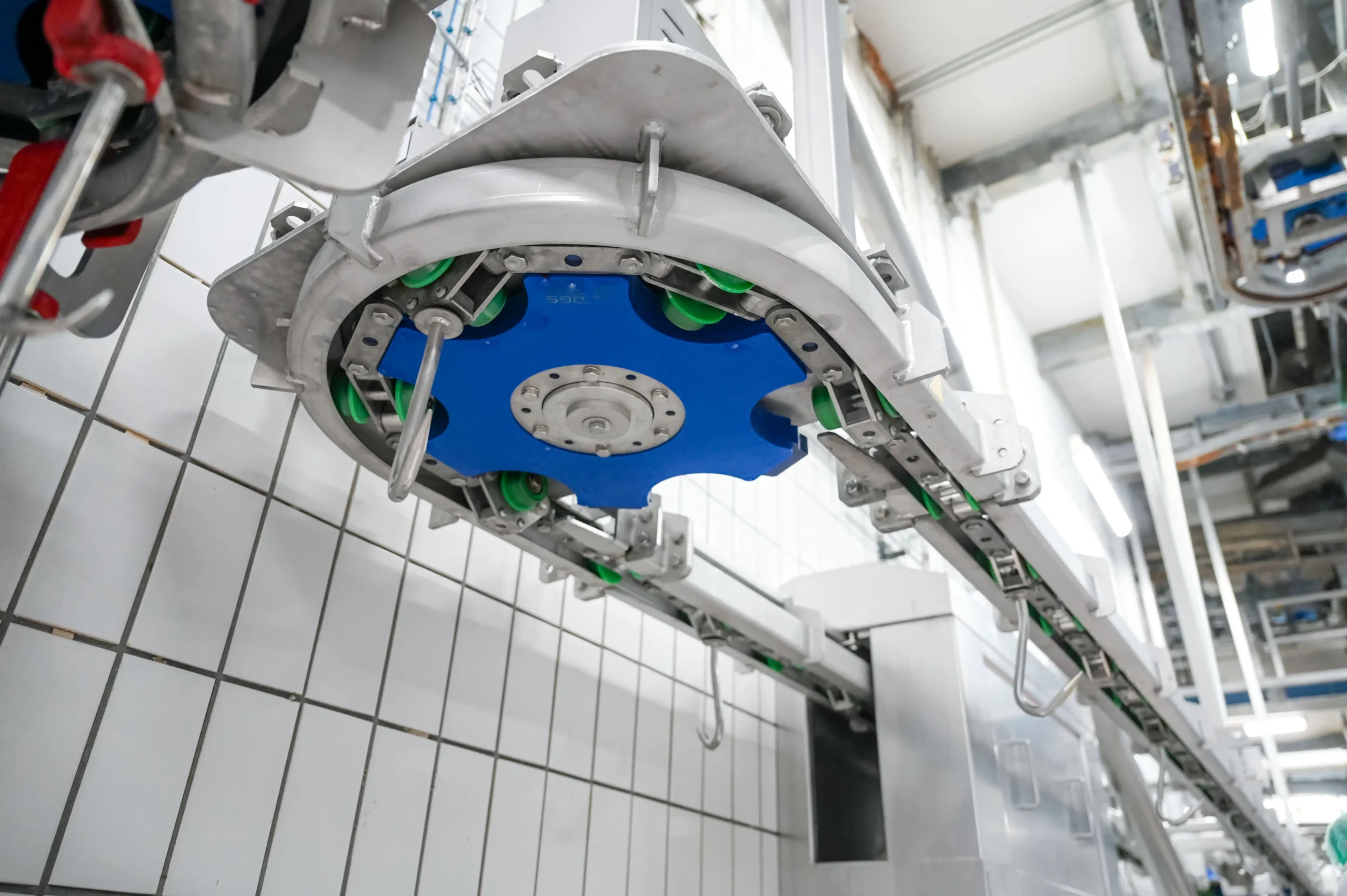

More informationStainless-Steel Chain: Preventing Fat Leakage on Carcasses

The stainless-steel chain is an innovative development from DGS that optimizes hygiene in abattoirs. Our stainless-steel chain offers numerous advantages over standard galvanized chains. Because the stainless-steel chains are lubricated and sealed before installation, lubrication during use is no longer necessary. This eliminates the risk of fat leakage from the chains onto the carcasses. Additionally, stainless-steel chains are maintenance-free and cost-saving.

More information

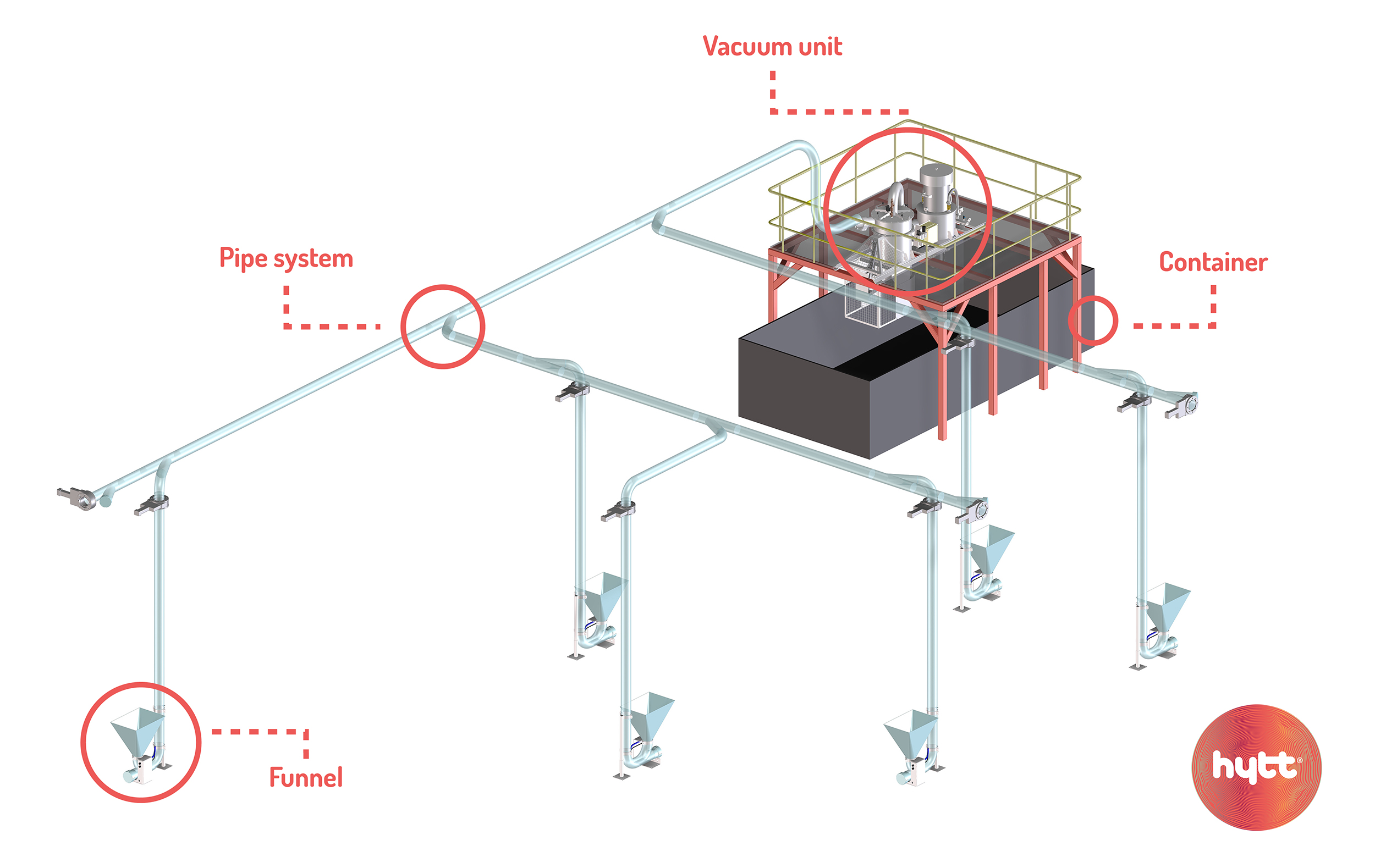

Efficient and Hygienic Waste Transport

In collaboration with our sister company HYTT, DGS offers an innovative solution for hygienically transporting waste in abattoirs. Our closed transport system utilizes vacuum techniques to suction product flows, waste, and animal by-products to a central location. This results in a cleaner and safer production area with reduced risk of cross-contamination.

- Upgrading waste and by-products

- Improved hygiene

- Sustainable and modular design

- Less water and cleaning required

Hygienic Organ Processing

DGS is committed to optimal hygiene during organ processing in abattoirs and offers various solutions for this purpose. After the takeover point, the organ hooks are cleaned by sterilization units to ensure they always return clean. Additionally, our gut conveyor belts are equipped with fixed carriers that efficiently separate the guts from each other. This allows the white organ package, red organs, and carcass to be offered simultaneously to the veterinary service.

Optionally, a valve can be installed where rejected guts fall through. This valve is operated by the veterinary service to prevent good white organ packages from being contaminated by rejected guts.

Organ conveyors